Green hydrogen is emerging as a pivotal player in the transition to sustainable energy, promising to significantly reduce greenhouse gas emissions and support the decarbonization of various sectors. Here, we delve into the numerous benefits and applications of green hydrogen, underscoring its potential to revolutionize our energy systems. In this article, you will know about meaning, types, pros and cons of Green Hydrogen, and its implementation in India. To explore more interesting UPSC Polity topics of GS Paper -3 like Green Hydrogen, check out other articles and IAS Notes of IASToppers.

Table of Content

- Introduction

- Types of Hydrogen

- Reasons to Develop Green Hydrogen

- Applications of Green Hydrogen

- Initiatives by India to Promote Green Hydrogen

- Hydrogen Production and Potential

- Challenges in Green Hydrogen Implementation

- Conclusion

- FAQs

Introduction

- Green hydrogen is hydrogen produced using renewable energy sources, such as wind, solar, or hydropower, to power the electrolysis process that splits water into hydrogen and oxygen.

- This method is considered environmentally friendly as it generates hydrogen without emitting carbon dioxide or other greenhouse gases, unlike traditional methods that rely on fossil fuels.

- Hydrogen is abundant, has energy density, and potential to reduce greenhouse gas emissions, and an attractive option for clean energy applications.

- As the lightest and most abundant element in the universe, hydrogen boasts a high energy content per unit mass, surpassing conventional fuels like gasoline and coal.

- Additionally, hydrogen serves as a versatile reducing agent with various industrial and energy applications.

Key Features of Green Hydrogen:

- Sustainable Production: Uses renewable energy sources through Electrolysis process which is emission-free.

- Environmental Benefits: No greenhouse gas emissions and reduces dependency on fossil fuels.

- Production Process:

- Electrolysis: An electric current is passed through water (H₂O), splitting it into hydrogen (H₂) and oxygen (O₂).

- Types of Electrolyzers include Proton Exchange Membrane (PEM), Alkaline Electrolyzers, Solid Oxide Electrolyzes.

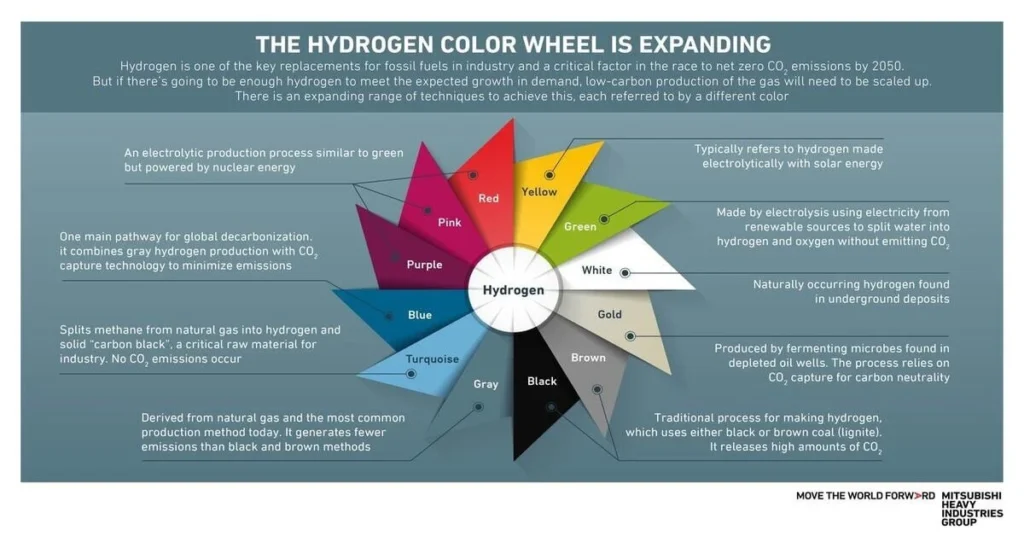

Types of Hydrogen

Hydrogen can be produced through various methods, each categorized by a color code that indicates the production process and environmental impact.

| Type of Hydrogen | Production Method | Process | Environmental Impact |

| Green | Renewable (solar/wind) | Electrolysis splits water into hydrogen and oxygen | Zero emissions, highly sustainable |

| Blue | Natural gas with carbon capture and storage (CCS) | Steam reforming of natural gas, CO₂ captured and stored | Lower emissions than grey hydrogen, still uses fossil fuels |

| Grey | Natural gas or methane without CCS | Steam methane reforming | High carbon emissions,unsustainable |

| Black | Using black coal | Gasification of coal | High emissions, most damaging |

| Brown | Using lignite (brown) | Gasification of lignite | High emissions |

| Pink | Electrolysis powered by Nuclear energy | Similar to green hydrogen but uses nuclear power | Low emissions, depends on perception of nuclear energy |

| Turquoise | Methane Pyrolysis | Methane split into hydrogen+ solid carbon | low emissions if powered by RE and solid carbon is managed |

| Yellow | Electrolysis using solar power | Similar to green hydrogen but specifically using solar energy | Zero emissions, highly sustainable |

| White | Naturally occurring in underground deposits | Extraction through drilling | Undefined, naturally occurring |

| Gold | Naturally occurring or produced by fermenting microbes | Found in depleted oil wells, relies on CO2 capture | Low-cost, extends life of oil fields, carbon-neutral with CO2 capture |

Reasons to Develop Green Hydrogen

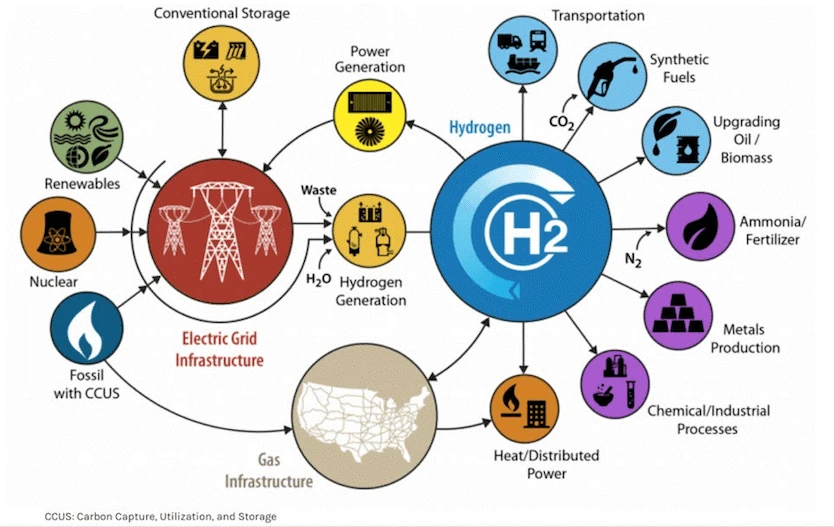

- Decarbonization of Hard-to-Abate Sectors: Green hydrogen can replace fossil fuels in industries such as steel, cement, and chemicals, which are challenging to decarbonize.

- Transportation: It can be used in fuel cells for heavy-duty vehicles, shipping, and aviation, where batteries are less effective.

- Reduction of Greenhouse Gas Emissions: Green hydrogen production emits no carbon dioxide, and helps countries meet their climate targets under the Paris Agreement.

- Energy Storage: Green hydrogen can store excess renewable energy (e.g., from wind or solar) and release it when needed, balancing supply and demand.

- Grid Stability: Provides a solution for intermittency issues associated with renewable energy sources, ensuring a reliable energy supply.

- Energy Security and Independence: Enables countries to produce their own energy, reducing dependency on imported fossil fuels and enhancing energy security.

- Diversification: Adds another layer of diversity to the energy mix, making the energy system more resilient.

- Economic Opportunities: Development of green hydrogen infrastructure and technology can create new markets and business opportunities.

- Job Creation: Generates employment in renewable energy sectors, electrolyzer manufacturing, and hydrogen infrastructure development.

- Innovation: Encourages research and development in clean technologies, leading to innovations that can be applied across various sectors.

- Global Leadership: Positions countries as leaders in the emerging green hydrogen economy, providing a competitive edge in the global market.

- Reduction of Air Pollution: By using green hydrogen in transportation and industrial applications reduces air pollutants such as nitrogen oxides (NOx) and particulate matter.

- Multiple Uses: Green hydrogen can be used in various applications, including power generation, heating, industrial processes, and as a feedstock for chemicals.

- Flexible Integration: Can be integrated into existing energy systems and infrastructure, facilitating a smoother transition to a low-carbon economy.

- Market Growth: Drives demand for renewable energy, stimulating further investment and growth in wind, solar, and other renewable technologies.

- Efficient Utilization: Ensures that renewable energy is efficiently utilized, even during periods of low demand or high production.

- Long-Term Sustainability: Relies on inexhaustible resources like water and renewable energy, ensuring long-term sustainability.

- Circular Economy: Promotes a circular economy by enabling the recycling of water and use of renewable energy.

Applications of Green Hydrogen

Energy Storage Solution:

- One of the most compelling advantages of green hydrogen is its ability to store energy.

- Renewable sources like wind and solar are intermittent, meaning their energy output can fluctuate based on weather conditions.

- It is produced via electrolysis using renewable energy, can be stored and converted back into electricity through fuel cells when needed, ensuring a consistent energy supply.

- Hydrogen can be stored and later converted back into electricity, helping to balance supply and demand in power grids dominated by intermittent renewable energy sources.

Transportation:

- Fuel cell electric vehicles (FCEVs) are at the forefront of sustainable transport technologies.

- These vehicles (cars, buses, trucks, trains), use hydrogen fuel cells to generate electricity, offering a carbon-neutral mobility solution.

- Companies like Hyundai scaled up production, to manufacture 500,000 hydrogen vehicles by 2030, and cities like Paris are adopting hydrogen-powered taxis and waste collection vehicles.

Industry:

- Green hydrogen is making inroads into industrial applications, notably in the chemical and petrochemical sectors.

- Ammonia Production: Hydrogen is a key component in the Haber-Bosch process, which combines hydrogen and nitrogen to produce ammonia, a vital ingredient in fertilizers.

- Methanol Production: Hydrogen reacts with carbon monoxide to produce methanol, clean hydrogen can substitute conventional hydrogen in this process to reduce emissions.

- Steel manufacturing: It is energy-intensive and traditionally relies on coal, for high temperatures and chemical reduction of iron ore, Hydrogen is being explored as a substitute.

Domestic Use:

- Some ongoing projects aimed at integrating green hydrogen into domestic energy systems.

- By replacing natural gas networks with hydrogen networks, homes can be powered and heated without emitting pollutants.

This transition can make residential energy consumption more sustainable.

Petrochemical Refining and Oil Production:

- Green hydrogen can mitigate the environmental impact of refining petroleum and producing oil.

- In the refining process, hydrogen is used to remove sulfur from crude oil, forming hydrogen sulfide, which is extracted further along in the process.

- This use is essential for producing low-sulfur fuels that meet environmental regulations, reducing carbon footprint, aiming for a gradual phaseout.

- Today, the majority of hydrogen is utilized by the refining and chemical industries, with demand having more than tripled since 1975.

- This hydrogen is predominantly produced from fossil fuels, often without carbon capture and storage (CCS).

- Clean hydrogen is poised to become crucial across various sectors, aiding in the transition to a sustainable energy future.

Hard-to-Abate Industries

- Certain industries are difficult to decarbonize due to their high energy consumption and CO2 emissions, coupled with challenges in electrification.

- Steel Production: Hydrogen can replace carbon-based methods in steelmaking, significantly reducing emissions.

- Cement Manufacturing: Hydrogen can provide the high-temperature heat required for cement production, reducing reliance on fossil fuels.

- Chemical Feedstock: Existing chemical processes, particularly those producing ammonia and methanol, can transition to using clean hydrogen, cutting down their carbon footprint.

Heavy Mobility

- Heavy-duty transportation modes are challenging to electrify due to their energy requirements and range needs.

- Trucks: Hydrogen fuel cells can power heavy trucks, providing a longer range and faster refueling compared to battery electric vehicles.

- Aviation: Hydrogen can be used directly in fuel cells or as a feedstock for synthetic fuels, helping to decarbonize air travel.

- Shipping: Hydrogen and ammonia (a hydrogen derivative) can serve as cleaner fuels for ships, reducing maritime emissions.

Additional Use Cases

- Decarbonizing Other Mobility Applications: Hydrogen can be used in light-duty vehicles, buses, and trains, complementing battery electric solutions.

- Domestic Heating: Hydrogen can replace natural gas in heating systems, providing a low-emission option for residential heating.

- Concrete Production: While hydrogen can’t directly replace current reactants in cement production, mixes of hydrogen with biomass or CCUS fossil fuels to reduce emissions.

Primary, Competitive, Secondary, and Least Competitive Hydrogen Applications

| Category | Application | Details |

| Feedstock | Ammonia-based Fertilizers | Ammonia production requires hydrogen for plant nutrition |

| Hydrocracking | Breaks down heavier petroleum fractions in refineries | |

| Hydrogenation | Saturates unsaturated compounds in vegetable oil production. | |

| Desulphurization | Removes sulfur from refinery oils | |

| Methanol Manufacturing | Hydrogen acts as a reducing agent. Biomass (less efficient, more energy-intensive) | |

| Competitive Applications | Iron and Steel Sector | Hydrogen reduces haematite to sponge iron, achieves high furnace temperatures. |

| E-Fuels | Produces fuels like methanol and kerosene by capturing CO2 and reacting with green hydrogen. | |

| Secondary Applications | Large Aviation | Suitable for long-haul flights due to high energy density and lightweight properties. Zero emission |

| Cement and Refractories | Replaces coal in cement production, achieving high temperatures, but is costly | |

| Shipping | Replaces marine diesel oil, reducing CO2 emissions | |

| Long-Distance Heavy-Duty Trucks | Offers longer range and shorter refueling times with hydrogen fuel cells | |

| Least Competitive Applications | City Gas Distribution | Blends hydrogen with natural gas to reduce carbon footprint. Requires more energy for transportation and commutation |

| Trains | Hydrogen fuel cell locomotives can replace diesel in remote and hilly regions. | |

| Metros and City Buses | Hydrogen fuel cell vehicles offer silent operation and zero emissions. Lithium battery alternatives |

Initiatives by India for Green Hydrogen

India defines green hydrogen as hydrogen produced via renewables-based electrolysis or biomass-based thermochemical pathways, with emissions less than 2 kg CO2 per kg of hydrogen produced.

National Green Hydrogen Mission:

- Launch Date: 15th August 2021, on India’s 75th Independence Day.

- Objective: To position India as a global hub for the production, usage, and export of green hydrogen and its derivatives.

- Targets: Produce 5 million tonnes of Green Hydrogen by 2030, aligning with renewable energy capacity growth, with the potential to scale up to 10 Mtpa based on growth of export markets.

- This initiative could contribute RE by adding 125 GW of RE capacity by 2030, and create 600,000 full-time jobs, facilitating a just transition from polluting sectors.

- Funds: Indian government allocated USD 2.4 billion, with an aim to attract USD 100 billion in private investment by the same year.

- Waivers on inter-state transmission charges and accounting towards renewable purchase obligations under the Green Hydrogen Policy implemented in February 2022.

- These measures are expected to reduce the costs of producing green hydrogen by 75%, targeting a production cost of USD 1-1.5 per kg by 2030.

- End Consumers: Transportation, chemical, and steel industries targeted to reduce one-third of all greenhouse gas emissions.

Mission Components:

- SIGHT Programme: Offers financial incentives (PLI) for domestic manufacturing of electrolysers and green hydrogen production to stimulate indigenous production and reduce reliance on imports.

- Pilot Projects: Supporting pilot projects in emerging sectors and production pathways will help test and scale up hydrogen technologies across various applications.

- R&D Projects: The Strategic Hydrogen Innovation Partnership (SHIP) aims to foster collaboration between public and private sectors to develop competitive hydrogen technologies.

- Skill Development: Coordinated training programs will address the skills gap and build a workforce capable of driving hydrogen technology development and deployment.

Green Hydrogen/Green Ammonia Policy 2022

- Free Transmission: Offers free transmission for 25 years, focusing on inter-State connectivity.

- Zone Setup: Plans to set up zones for manufacturing green Hydrogen and ammonia.

- Storage Land: Port authorities to provide land for storage purposes at applicable rates.

- Industry Mandates: Industries like oil refining, fertiliser, and steel may be required to use green Hydrogen for a portion of their needs.

Private Investments in Hydrogen Energy

- Reliance and L&T: Invest in hydrogen energy creation, including research on green hydrogen technology.

- Indian Oil Corporation: Plans to construct a green hydrogen plant at its Mathura refinery.

- GAIL and NTPC: Intend to build India’s largest green hydrogen plant.

NITI AAYOG Report – ‘Harnessing Green Hydrogen – Opportunities for Deep Decarbonisation in India’ 2022

- Demand Growth: India’s hydrogen demand could quadruple by 2050, comprising nearly 10% of the world’s total.

- Industrial Decarbonization: Green hydrogen crucial for decarbonizing hard-to-change sectors like fertilisers, refining, methanol, maritime shipping, iron and steel, and transportation.

- Emission Reduction: By 2050, green hydrogen could reduce CO2 emissions by 3.6 gigatons.

- Manufacturing and Exports: A competitive green hydrogen industry could unlock significant electrolysis capacity and export markets for green hydrogen and related products.

International investments:

- India announced 48 green hydrogen projects (capacity 3.5 Mtpa), under Multilateral development banks like World Bank, Asian Development Bank, German development Agency.

- The National Green Hydrogen Hub Development Plan proposed 25 first-generation green hydrogen projects and five green hydrogen hubs by 2025.

- These are located in coastal states– Gujarat, Karnataka, Maharashtra, Kerala, and Andhra Pradesh.

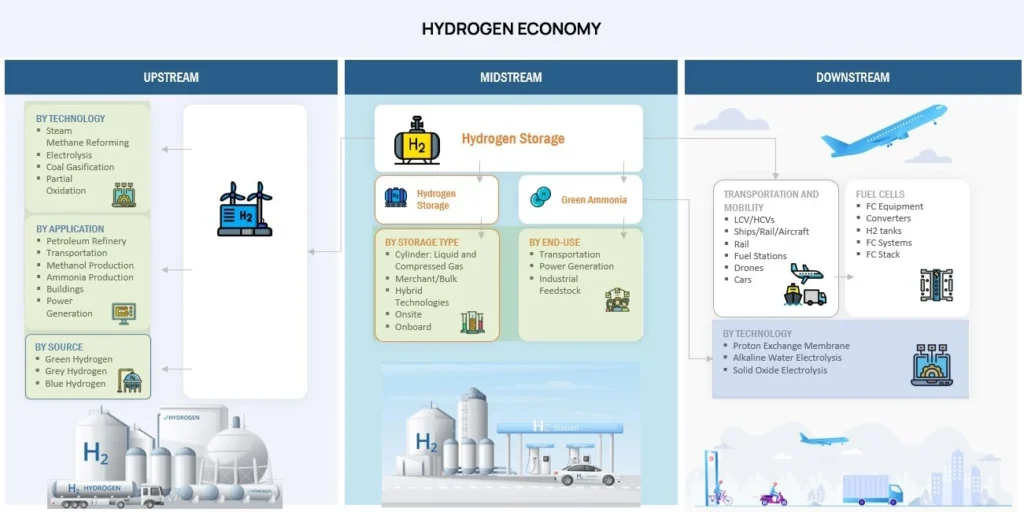

Hydrogen Production and Potential

- Currently, India produces around 6 million tonnes of hydrogen annually, primarily for petroleum refining, ammonia production, and steel manufacturing.

- Most of this hydrogen is produced through fossil fuel-based processes, but pilot projects exploring green hydrogen production using renewable energy and biomass.

- By 2040, hydrogen demand could increase, driven by the refinery and fertilizer sectors.

- It is projected that India’s green hydrogen production costs could fall to USD 0.75 per kg by 2050, potentially making it one of the cheapest producers globally.

- This cost advantage could position India as a major player in green hydrogen export markets, although transportation costs will play a crucial role.

Hydrogen Economy

The HASH Framework

- Hydrogen Applications Segmentation and Hierarchy Framework (HASH) has been developed based on pros and cons of hydrogen (as fuel and feedstock) to prioritize its use.

- It provides a comprehensive analysis of the hydrogen ecosystem in India, identifying priority sectors for investment and areas where hydrogen applications are less feasible.

- This strategic approach ensures efficient resource allocation and maximizes the impact of hydrogen on India’s energy transition.

Challenges and solutions for Green Hydrogen Implementation

- Cost-effectiveness: Energy access in remote areas, might not be as efficient compared to alternatives like direct electrification with distributed renewables and microgrid solutions.

- While hydrogen offers high gravimetric energy density, but its volumetric energy density poses challenges, complicating storage and utilization.

- Moreover, current production methods have environmental drawbacks, with SMR emitting significant carbon dioxide.

- Green hydrogen production, though cleaner, faces cost barriers due to raw material requirements like platinum and rubidium.

Environmental sustainability:

- The biomass used for hydrogen production must be sustainable to avoid net positive emissions from deforestation.

- Water scarcity is another critical issue, as green hydrogen production could require around 50 billion liters of demineralized water by 2030.

- Recycling industrial or municipal wastewater is proposed, but its capacity is limited and faces competing demands, particularly in agriculture.

- Issues like land availability, proposing land banks for renewable and green hydrogen capacity deployment with fair policies to prevent displacement and environmental degradation.

- The mission calls for creating land banks with fair and rational policies, but environmental and social protections are necessary to prevent displacement and environmental degradation.

Solutions for Energy Sector

- India’s energy mix is heavily reliant on coal, making it a net energy importer and exposing it to market volatility and unstable energy bills.

- India aims to achieve energy independence by 2047 and net zero emissions by 2070.

- Despite being the fourth-largest globally in renewable energy capacity, renewables contribute 20% to electricity generation, with recent growth driven by solar PV and onshore wind.

- India faces challenges in expanding its renewable capacity due to water and land scarcity.

- To address this, the country is exploring offshore wind, marine, tidal energy, and various energy storage options.

- India has set ambitious targets to install 500 GW of non-fossil energy capacity and achieve 50% electricity generation from renewables by 2030.

- There is lack of commercial-scale green hydrogen production, essential raw materials for electrolyzers, and adequate infrastructure for hydrogen storage and transportation.

- India needs a strategic framework that prioritizes hydrogen demand centers and optimizes infrastructure utilization.

- By leveraging its abundant renewable resources and fostering domestic production capabilities, India can realize its potential as a self-reliant green hydrogen producer and exporter.

- India needs a strategic framework that prioritizes hydrogen demand centers and enable efficient utilization of raw materials and infrastructure.

Conclusion

Clean hydrogen is set to revolutionize various industries by providing a sustainable alternative to fossil fuels. From traditional uses in ammonia, methanol, and oil refining, to emerging applications in steelmaking, concrete production, heavy mobility, and energy storage, hydrogen’s versatility and potential for emission reductions make it a cornerstone of the global energy transition. India’s ambitious policy framework and substantial investments further highlight the country’s commitment to becoming a leader in the green hydrogen economy. Developing green hydrogen is essential for achieving a sustainable and low-carbon future. It offers a versatile, clean, and efficient solution to many of the energy and environmental challenges facing the world today. As technological advancements continue and production scales up, green hydrogen is set to play a critical role in achieving a more sustainable and resilient energy future.

Ref:Source-1

| Other Articles in Environment & Disaster Management | |

| National Hydrogen Mission | Environmental Impact Assessment (EIA) |

| Biofuels | National Green Tribunal |

| Green GDP | Central Pollution Control Board (CPCB) |

FAQs (Frequently Asked Questions)

What are the limitations of green hydrogen?

High energy consumption: the production of hydrogen in general and green hydrogen in particular requires more energy than other fuels.

Safety issues: hydrogen is a highly volatile and flammable element and extensive safety measures are therefore required to prevent leakage and explosions.

Does using (green) hydrogen have a competitive cost?

Currently, neither renewable hydrogen nor blue hydrogen are competitive in terms of cost compared to grey hydrogen. Green hydrogen will become competitive compared to grey and blue hydrogen by 2030, mainly due to scaling up of the electrolyzer industry, its automation and innovation

Where is India’s first multipurpose green hydrogen project situated?

SJVN Limited, a leading hydropower company, inaugurated India’s first multipurpose green hydrogen pilot project at its Nathpa Jhakri Hydro Power Station (NJHPS) in Himachal Pradesh.

What are electrolyzers?

An electrolyzer is an electrochemical device made of membranes and electrolytes; when it is powered by electricity, it can break the chemical bonds in a water molecule, separating hydrogen and oxygen, which can then be collected and stored.

What are Fuel Cells?

A fuel cell is an electrochemical device similar to an electrolyzer. It is made of membranes and electrolytes that are sometimes identical to the ones found in an electrolyzer, but it reverses the process: it uses hydrogen to create electricity.

The molecules of the fuel (H2) and of the combustive agent (usually oxygen, O2) are broken down into positive ions and electrons, which then go through an external circuit, generating an electrical current. The H+ and O- ions then combine, creating water (H2O) as its only waste product.