The National Green Hydrogen Mission (NGHM) introduced by the Ministry of New and Renewable Energy (MNRE) recently includes a new set of incentives termed “Mode 2” for the production of green hydrogen and green ammonia.

- Earlier, first set of incentives are termed as Mode 1, under the NGHM was announced.

About the Mode 2 Incentives under NGHM:

- The Mode 2 focusses on green hydrogen (Mode 2B) and green ammonia (Mode 2A) production.

- The schemes are based on Demand Aggregation Model, which involves implementing agencies aggregating demand and conducting bids for the lowest cost supply of green hydrogen and its derivatives.

About Green Hydrogen Production (Mode 2B):

- Implementing Agencies: Oil and gas companies nominated by the Ministry of Petroleum and Natural Gas.

- Process: Each company will aggregate demand for its refineries and conduct bids.

- Capacity for Bidding: 2,00,000 metric tonnes per annum.

- Incentive Payout: Based on the Rs/kg of green hydrogen and actual production.

About Green Ammonia Production (Mode 2A):

- Implementing Agency: Solar Energy Corporation of India (SECI).

- Incentive Structure: Rs 8.82/kg in the first year, decreasing annually over three years.

- Capacity for Bidding: 5,50,000 metric tonnes per annum.

About Mode 1 Incentives under NGHM:

- Incentive Caps: Rs 50/kg in the first year, reducing annually over 3 years.

- Participation: Includes bids from major energy and infrastructure companies.

- Budget Allocation: Rs 19,744 crore, with Rs 17,490 crore for production-linked incentives.

About the National Green Hydrogen Mission (NGHM):

- The NGHM aims for India’s transition from fossil fuels to renewable energy sources and aims to make India a global hub for the production, utilization, and export of green hydrogen.

- It was launched in 2023 with an initial outlay of Rs. 19,744 crores.

Objectives:

- To develop a green hydrogen production capacity of at least 5 Million Metric Tonnes (MMT) per annum by 2030, supported by about 125 GW of associated renewable energy capacity.

- To achieve a cumulative reduction in fossil fuel imports by over Rs. 1 lakh crore and an abatement of nearly 50 MMT of annual greenhouse gas emissions.

Financial Allocation:

- The funds allocated in decreasing order to different component includes the Strategic Interventions for Green Hydrogen Transition (SIGHT) programme, pilot projects, Research and Development (R&D), and other mission components.

Implementation of the scheme:

- States and regions will be identified and developed as Green Hydrogen Hubs, which can be capable of supporting large-scale production and utilization of hydrogen.

- SIGHT Programme will focus on funding the domestic manufacturing of electrolysers and the production of green hydrogen.

- A public-private partnership framework for R&D (Strategic Hydrogen Innovation Partnership – SHIP) and a coordinated skill development programme will be established.

- An enabling policy framework will be developed, including robust standards and regulations, to support the establishment of the Green Hydrogen ecosystem.

Challenges and the Way Forward:

- High Production Costs: Producing hydrogen from renewable sources is currently more expensive than from fossil fuels, which hampers its widespread adoption.

- Manufacturing Base: India’s fundamental manufacturing base is relatively weak, posing a challenge to becoming a high-technology manufacturing hub.

- Coordination Across Sectors: Success requires a coordinated effort from various ministries, departments, institutions, and agencies at both the central and state levels.

- Infrastructure Development: Focus on enhancing infrastructure for small manufacturing and allied enterprises, which are vital for the green economy.

About Green Ammonia:

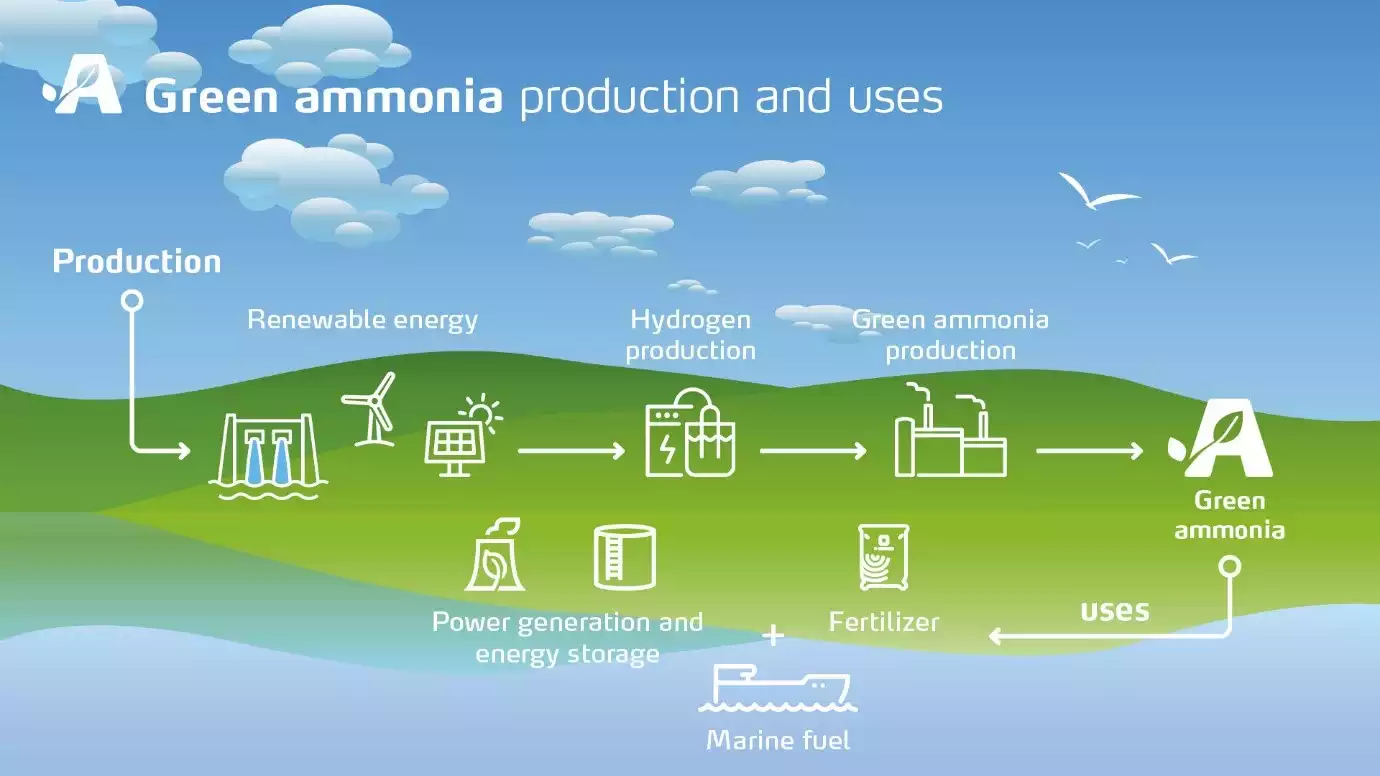

- Green Ammonia is ammonia (NH₃) produced through a process that is carbon-neutral.

- It is made by using renewable energy sources, like wind or solar power, to electrolyze water into hydrogen and oxygen.

- The hydrogen is then combined with nitrogen extracted from the air to produce ammonia.

Production Process:

- Electrolysis of Water: Using electricity from renewable sources to split water into hydrogen and oxygen.

- Haber-Bosch Process: The hydrogen is then combined with nitrogen to produce ammonia.

- This process must be powered by renewable energy to be considered ‘green’.

Applications:

- Fertilizer Production: Ammonia is a critical component in fertilizer manufacturing.

- Energy Storage and Carrier: Green ammonia can store and transport hydrogen energy efficiently.

- Maritime Fuel: It can be used as a cleaner alternative as fuel for ships.

About the Green Hydrogen:

- The Green Hydrogen is hydrogen gas produced by the electrolysis of water, where the electricity used in this process is derived from renewable energy sources like solar, wind, or hydroelectric power.

- This method is environmentally friendly as it does not produce greenhouse gases during production, contrasting with grey or blue hydrogen, which are produced from fossil fuels and natural gas respectively.

Benefits:

- It can significantly reduce carbon emissions, particularly in hard-to-decarbonize sectors like transportation, industry, and heating.

- It offers an alternative to fossil fuels, contributing to energy diversification and security.

- It can be used to produce green ammonia.

Ref: Source

| UPSC IAS Preparation Resources | |

| Current Affairs Analysis | Topperspedia |

| GS Shots | Simply Explained |

| Daily Flash Cards | Daily Quiz |